What We Do

You may know us for awards, name tags or gifts we've helped you with over the years - but do you know how much VAE has to offer developers, contractors and architects?

There are a multitude of things we can do but haven't done yet or didn't manage to snap pictures of before they left the building, which makes them hard to advertise.

We can engrave into a wide range of materials and with our many years of experience and our talented design staff we can help you navigate away from options that we know won't hold up to an environment or use, all while keeping aesthetics and the desired "feel" of the completed space in mind.

We've engraved or designed and sourced our fair share of:

- Pavers/Bricks

- Exterior and interior plastic signs Subtractive (more eco friendly) ADA compliant braille signs

- Signs made from interesting materials clients bring in, like wood from the build site, stones unearthed on the property, etc.

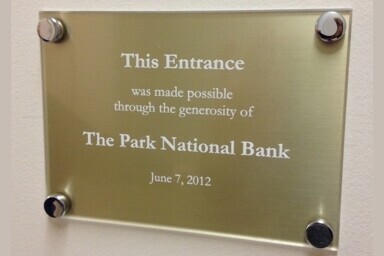

- Glass and stand-off signs

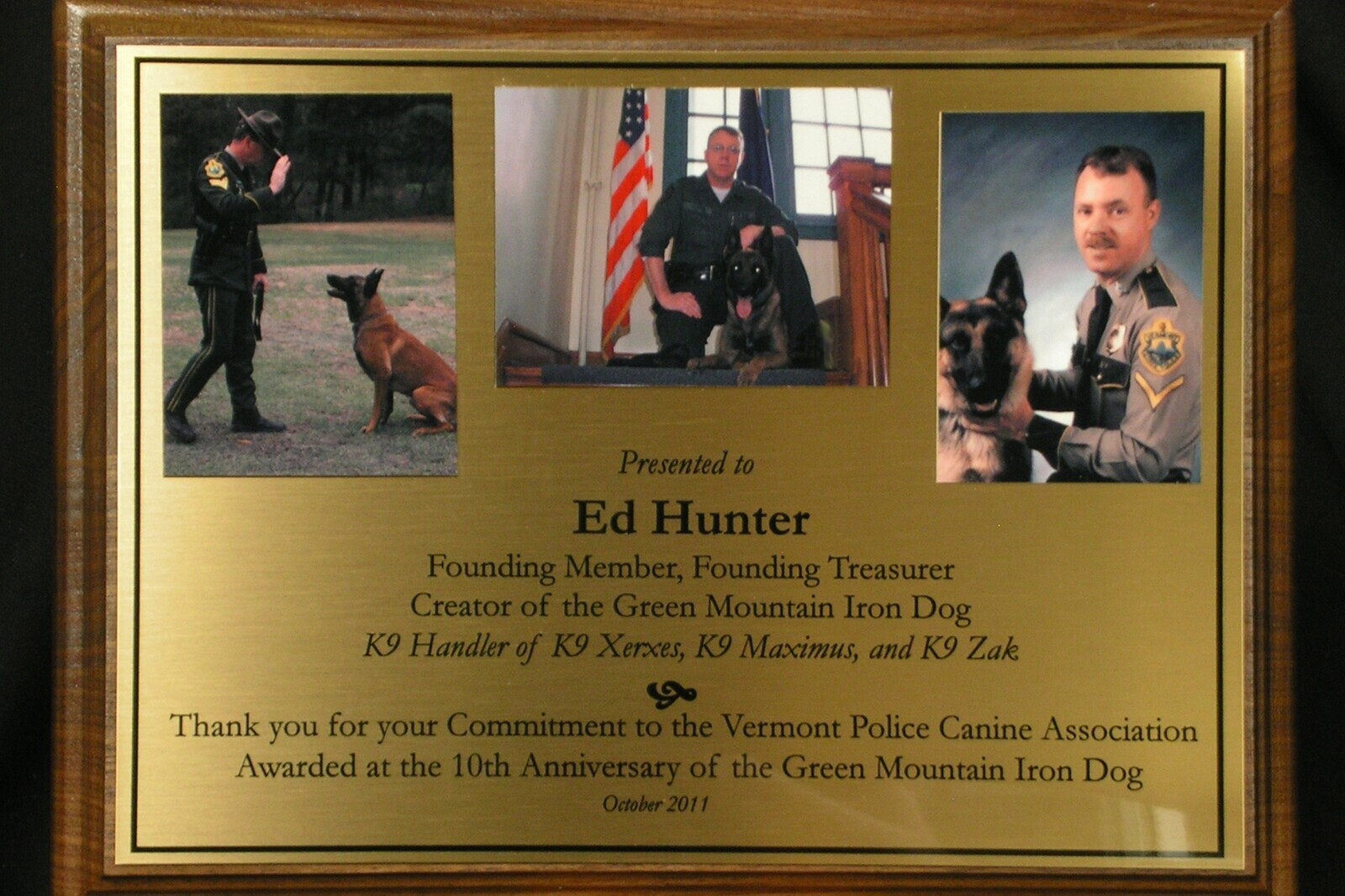

- Signs with wording and photos or graphics engraved directly into the wood

- Tools of all sorts

- Ceremonial shovels

- Groundbreaking keepsake gifts

- Door knockers

- Key tags and room numbers

- Signage for offices like staff directories, "in use/vacant" signage, door signs, etc.

- Signs that detail rates or hours

- Signage or ID tags for machinery, breakers, or anything else that needs specific, easy to read (but difficult to vandalize) permanent instructions

- Larger decorative plaques with company mission statements for lobbies or conference rooms

- Project completion plaques or awards

- Glass light fixture covers

- Cast metal plaques and signs

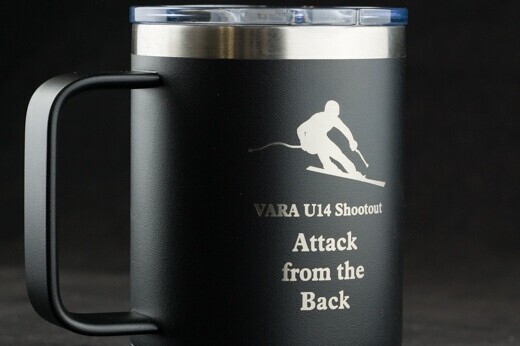

- Ad specialty bulk items

- Banners and stickers

- And some examples of things we would love to try or want the opportunity to help design and engrave more of:

- Wooden stair faces or tops prior to staining, sealing and installation

- Glass sheets for displays, decorative windows, etc.

- Glass door inserts

- Mirrors

- Mantle pieces

- Archway keystones

- Car parts

- Really, if you have the time, budget and are looking for input, then if it'll fit in the machine (or we can rig a way to make the parts that need engraving to fit) then our combined imaginations are the limit!To give a brief summary of current capabilities:

- Diamond drag engraving on metal:Most commonly into brass, pewter, silver, copper, aluminum and steel. Cylindrical maximum diameter: 10". Maximum length in our largest vise: 36". Standard flat metal capacity: 15" x 18" Specialty pass thru long plate: 20" by any length

- Sand carving stone, concrete, glass and crystal:Approximately 18" x 30" standard capacity inside cabinet, one outfitted with extended or pass thru option for larger items.We recently acquired a portable blasting pot and grit that's safe to "release back into the wild" so during warm months we will have the capability to do extra large items outside like door inserts, boulders, slabs, large mirror balls, etc. Note: concrete, even smooth top, and most "found" stones we've had brought in do have hard spots that do not blast at the same rate as the surrounding material, or that may chip out during engraving. We will assess the risks and offer recommendations during the design process to minimize the likelihood of those being noticeable and typically suggest paint fill for optimal contrast and to visually smooth out bumpiness in gritty materials. If you are looking for clean fine detail or small lettering we would strongly recommend using marble or smoothly finished slate. While masks for blasting are designed with software, the actual blasting process is done by hand, so scheduling for larger sand carving jobs may extend beyond our typical turnaround times.

- Laser engraving wood, plastics, acrylic, anodized aluminum by request, leather and more:120w Laser's bed capacity is 40" x 24", but is able to be set up for pass thru on larger items (which we are currently looking into adding to expand that machine's capabilities) with 8" cylindrical capacity80w Laser's bed is 20" x 32" with 8" diameter cylindrical capacity. For more technical info please contact us at info@vermontawards.com for more in depth technical information on our machinery and capabilities!

This sounds so cool (and it is).

A beam of light burns into the substrate (product) either reacting with elements in the product (silica in bricks), simply burning (wood), or by coating the substrate with a carbon solution that causes a bond. There are many things that engrave beautifully this way. Wood, plastic, bricks, acrylics, it’s great. For metal – it stinks. We know, most of our industry produces wood plaques with coated metal plates on their lasers – generally the only machines they have. Here are some examples of what’s great and what’s not.

The old-fashioned way has, rightly, been supplanted for many applications.

We used to do everything this way. Now we mostly use them for metal engraving because they run on air pressure – meaning they can cut into the metal and the software we use allows for beautiful fill patterns. Here are examples of why we will never laser award plaques.

Using our Newing-Hall engraving machines we can engrave up to 20" x infinity (theoretically) but that gets into custom metal fabrication. We once bought a 72" x 28" aluminum plate a bus ticket from Boston.

In the awards and engraving industry, sublimation is a full-color process that embeds dyes into specially coated products – it is permanent, doesn’t fade or flake, and can’t be picked at like silk-screening.

A lot like sandblasting, only with a very fine grit that allows for delicate depth and detail.

Once upon a time, we did glass by rotary engraving, then tried the laser, but were never satisfied. The deep etch, shading possibilities, and hands-on artistry of sand carving in glass sold us. Glass, rocks, marble, slate, almost anything can be etched, given the time to create the artwork and the skill to create the finished product.

Why do we bother to offer this when you can order them online cheaper? Here’s a reason.

Annually we order high-quality medals for UVM with the green and gold ribbon we’d all recognize. One year they came in aqua and gold. What would you do? Us? We shipped the medals back and had the company reattach all the ribbons. Thanks to our ongoing relationship – with future orders at risk – we can be assured of service an Internet customer might not.

Similar to the above, we have also found that we can often beat the online prices (you will find hidden costs like run charges, setups, etc.) and again we offer an ongoing relationship. We belong to Sage, which gives us access to zillions of products at all price points (would you believe an outdoor kitchen for $7,000? Naturally it would have your logo on it)!