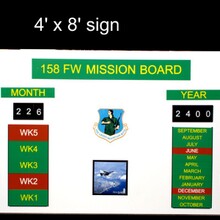

Engraving & Design

When it has to be special, you want to know that the award, gift, or sign was made by someone who pays close attention to detail and cares about the end result. All of our work is proofed at least twice, not just for accuracy, but also for design.

We are meticulous when it comes to which method we use for a given order as it needs to be the method (sand carving, rotary engraving, laser engraving, or sublimation) that will create the best outcome. This is why we’re committed to rotary engraving metal – it has texture and sparkle that is simply not achievable with the quicker laser process. We sand carve glass because it has depth and clarity not possible with the other processes. Plastics, acrylics, leather, and wood are wonderful laser engraved. We'll work with you to bring your vision to life.

Custom Design

We love offbeat jobs - they keep us on our toes and interested. Sometimes customers come to us not knowing what they want, and others have the idea clearly defined. Either way, it works and we have a lot of fun throughout the process!

Sand Carving

A high-quality process that involves a mask, transfer print, careful application, and manual directing of sand is required. It may appear to be straightforward, but the sand carving process requires the greatest level of expertise.

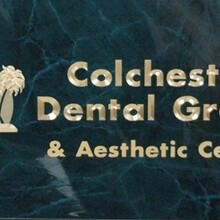

Rotary Engraving

Engraving with a diamond is difficult because we only have two colors to work with- the background and the material beneath. That is precisely what makes our software so amazing- we can produce any number of cutting paths in place of the colors in a logo or design. This is a difficult exercise that takes years to master, but the results are well worth it.

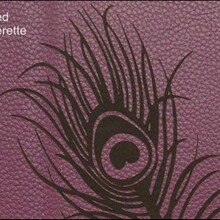

Laser Engraving

Black and white artwork is generally necessary for laser engraving. Our laser is ideal for wood, plastics, acrylics, bricks, and some glass. We don’t typically laser metal as it looks much better engraved with the rotary process. While lasering uses the same graphics program as sublimation, significantly greater machine skills are required.

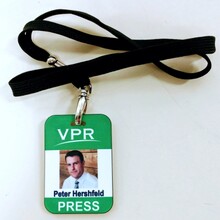

Sublimation

We can go wild with color when we use sublimation! However, photographs or drawings must be high resolution in order to be used. The process begins with the same graphics software used for the laser, and involves creating a transfer that is then embedded into specifically treated metal, plastic, ceramics, or glass. It is one of the most affordable techniques we have available.